Center Introduction

Introduction of 1. Technology Center

The technical center of Sichuan Haida Rubber Group Co., Ltd. (hereinafter referred to as: Haida Group) is the product research and development and design of vehicle tires (including semi-steel passenger radial tires, all-steel commercial radial tires and commercial bias tires) and special rubber products involved in the main business and auxiliary business of Haida Group, and provides technical support for its manufacturing and operation. The Technology Center of Haida Group was recognized as the Enterprise Technology Center of Sichuan Province by the People's Government of Sichuan Province in 2004.

Hainda Group Technology Center has nearly 197 professional automotive rubber tire technicians, including 25 senior technical titles, 123 intermediate technicians and 49 junior technicians. Among them, the experimental detection center is through.

Haida Group has successively obtained

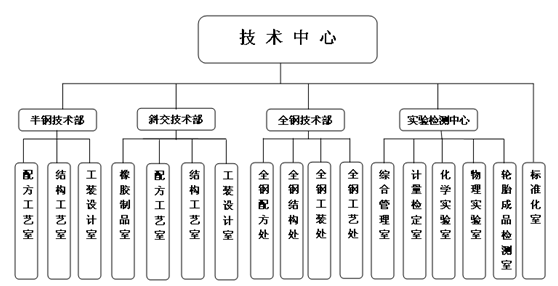

Organizational Structure of 2. Technology Center

The technology center of Haita Group is composed of five major plates: semi-steel technology department, oblique technology department, all-steel technology department, experimental testing center and standardization room.

3. R & D capability

The semi-steel technology department, the bias technology department, and the all-steel technology department are mainly engaged in the product research and development and design of various vehicle tires, special rubber products, and retreaded tires. They have strong technical force, and all personnel have a comprehensive professional theoretical foundation and rich Practical experience. With all-steel commercial radial tires, semi-steel passenger radial tires, commercial bias tires, rubber liners, special rubber shock-absorbing products, V-belts, rubber miscellaneous products and other product development and design capabilities.

The main tire industry has more than 1000 specifications in three categories: semi-steel passenger radial tires, all-steel commercial radial tires and commercial bias tires, covering construction machinery, truck, light truck, large passenger car, medium passenger car, PCR, UHP, SUV and other commercial vehicles and passenger cars.

Semi-Steel Technology Department: Mainly for semi-steel passenger radial tire product structure design, formula design, tooling mold design and product process improvement, production process technology control.

All Steel Technology Department: Mainly for all-steel commercial radial tire product structure design, formula design, tooling design and product process improvement, production process technology control.

Oblique Technology Department: Mainly for commercial bias tires, rubber products product structure design, formula design, tooling mold design and product process improvement, production process technology control.

Standardization Room: Mainly responsible for standardized document management and external intelligence management.

4. experimental detection ability

Car tire rolling resistance testing machine

The experimental testing center is a secondary experimental testing organization under the technical center of Haidong Group. It is mainly engaged in the testing of tire performance such as car tires, truck tires, agricultural tires, industrial tires, etc., the physical performance testing of rubber products, and the physical and chemical analysis of tire raw materials. The testing agency passed China's conformity assessment in May 2009.

The center has a sound management system and strong technical force, all personnel have a comprehensive professional theoretical basis and rich practical experience. With tires, rubber production raw materials, tire semi-finished products, tire products and other aspects of chemical, physical, mechanical, safety performance and other testing capabilities.

The experimental testing center has complete testing equipment, equipped with nearly 60 sets of testing equipment such as tire high-speed durability testing machine and tire rolling resistance testing machine, and can carry out EU ECE R54 and ECE R30 tire load tests, US FMVSS109/FMVSS119/ FMVSS139, India IS 15633 and IS 15633, Brazil INMETRO NO. 205 and INMETRO NO 165, Iraq IQS:229 3/1/2011 and

Integrated Management RoomResponsible for the effective operation of the entire laboratory quality management system, external sample management, various records and the management of personnel training in the entire experimental testing center.

Tire Testing Research and Development Center: It has TJR-RR-PC(Y) type car rolling resistance testing machine, TJR-2-PC(Y) type high-speed mileage testing machine, CX-YLN-1214, CX-YLN-1212, N6/120-1,Y-A and other tire durability testing machines, LQTJ-111 type tire strength testing machine, tire hydraulic blasting machine, tire air tightness testing and other tire performance testing devices. The laboratory mainly carries out tire rolling resistance test, outer edge size test, tire strength performance test, car tubeless unring resistance test, tire durability test and high-speed performance, tire air tightness test and many other tests.

Chemical Laboratory: It has nearly 18 chemical analysis instruments and equipment such as melting point meter, carbon black coloring strength, oil quality analysis, etc., and can carry out nearly 100 chemical detection and analysis of various tire production raw materials such as rubber, carbon black, rubber active agent, rubber antioxidant, rubber accelerator, etc.

Physics Laboratory: It has nearly 30 testing equipment such as American Alpha MDR2000 Vulcanizer MV2000R Mooney Viscosity Meter, UT -20.6 million Energy Material Testing Machine, GT-RH-20 Compression Heat Generator, IU-2710 Ozone Resistance Testing Machine, etc, it can carry out conventional physical performance testing of various rubber properties such as processing performance of mixed rubber, tensile, ozone, hot air aging, compression heat generation of vulcanized rubber, and more than 120 physical performance testing tests of various raw materials such as tire raw material skeleton materials-steel cord, bead wire, polyester cord, nylon cord, etc.

Metrological verification room: The establishment of pressure, length, weighing instrument, electrical, thermal, differential pressure flowmeter, electric unit combination instrument and other measurement standard devices, was awarded"