Haihong Company

Sichuan Haihong Rubber Products Co., Ltd.

1. Company Profile

Sichuan Haihong Rubber Products Co., Ltd. is a wholly-owned subsidiary of Wuliangye Group. Sichuan Haida Rubber Group Co., Ltd. (hereinafter referred to as Haida Group) is a joint stock limited company jointly invested and established with private capital. It is a civil welfare enterprise supported by governments at all levels. The company was established in October 2005 with a registered capital of 2.2 million yuan, more than 100 employees and an annual sales income of more than 50 million yuan.

The company is located in Yangma Town, Jianyang City, Sichuan Province, adjacent to Chengzi Industrial Park, with convenient transportation and convenient road and railway transportation.

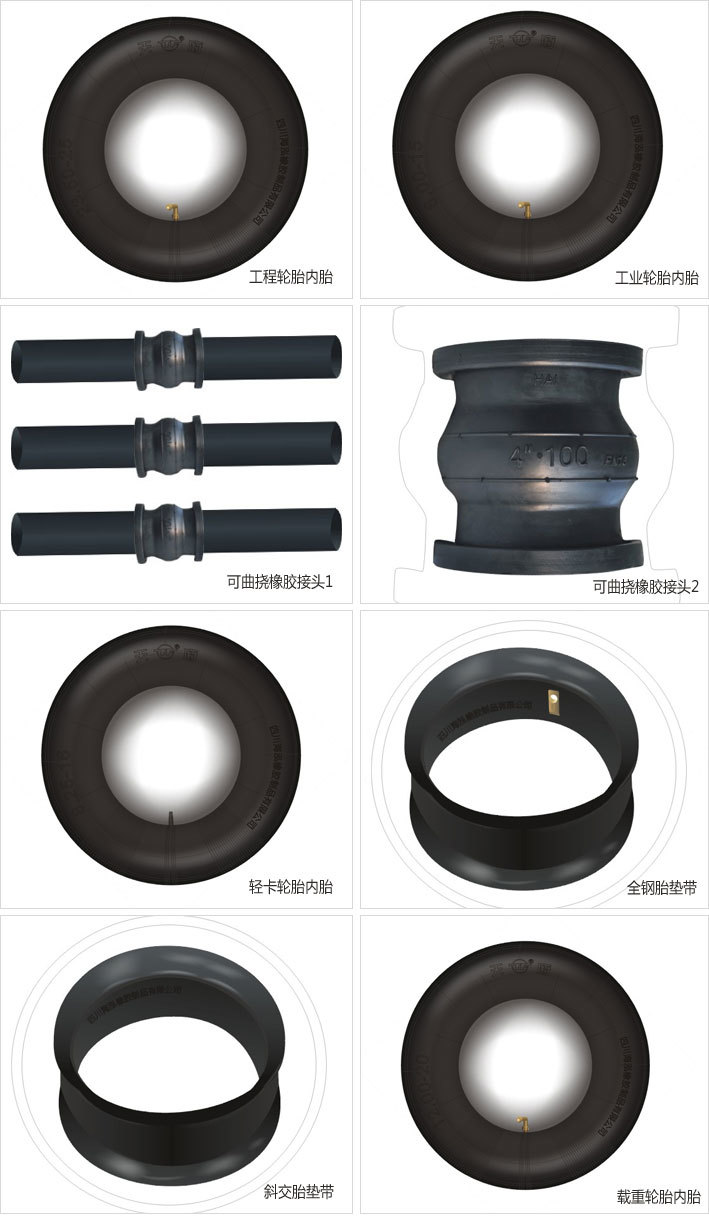

The company relies on the strong technical research and development force of Haigu Group, has domestic advanced inner tube, cushion belt production and testing equipment, specialized production, processing and sales of "Tianfu", "Haihong" brand series of natural rubber inner tube, bias tire cushion belt, all-steel cushion belt and rubber joints and other rubber products. At present, there are 35 inner tube specifications and more than 20 cushion belt specifications, which can be used with light truck radial tires, mini radial tires, truck bias tires, light load bias tires, construction machinery tires, agricultural tires, industrial tires, etc. The company passed ISO/TS16949

The company insists on taking the road of quality and benefit, constantly enriching products and improving product quality. By the end of the 12th Five-Year Plan, the sales revenue will strive to reach 80 million yuan and become the central and western regions.

Company business philosophy: self-transcendence, everything for the better.

Company goal: Dedication efficiency, refinement and innovation. Pursuit

Employee Code of Conduct: Love, Responsibility, Passion

Staff rules: unity and fraternity, compliance, dedication, dedication, standardized operation, excellence.

Company address: Chuanxiang Road, Yangma Town, jianyang city, Sichuan Province

Contact Phone:028-27729199Fax:028-27729202

2. Products

1.1, natural inner tube technical indicators

| experimental project |

Unit |

Index requirements |

| Tensile strength |

Mpa |

≥14.7 |

| Elongation at break |

% |

≥500 |

| Rate of decline in tensile strength after aging |

% |

≤10 |

| Hot tensile deformation rate |

% |

≤25 |

| joint strength |

Mpa |

≥8.3 |

| Adhesion between rubber cushion valve and tire body |

Kn/m |

≥3.5 |

| Adhesion between valve with rubber seat and rubber pad |

Kn/m |

≥3.5 |

1.2 specifications and dimensions

| Kind |

Inner tube specification |

Width of flat stack section(Not lessmm) |

Flat stack outer perimeter(Not lessmm) |

Weight (not lessg) |

valve model |

| Engineering tire series |

23.50-25 |

600 |

4214 |

19000 |

Z1-01-8 |

| 20.50-25 |

560 |

4000 |

15000 |

Z1-01-8 |

|

| 17.50-25 |

420 |

3580 |

10035 |

Z1-01-8 |

|

| 14.00-20 |

360 |

3109 |

8500 |

Z1-01-8 |

|

| 13.00-20 |

370 |

3100 |

5800 |

Z1-01-8 |

|

| Truck tire series |

12.00-20 |

310 |

2909 |

4500 |

Z1-01-8 |

| 11.00-20 |

290 |

2759 |

3980 |

Z1-01-8 |

|

| 10.00-20 |

270 |

2668 |

3500 |

Z1-01-8 |

|

| 9.00-20 |

250 |

2608 |

3000 |

Z1-01-6 |

|

| 8.25-20 |

230 |

2517 |

2600 |

Z1-01-5 |

|

| Light Truck Series |

8.25-16 |

240 |

2211 |

2100 |

Z1-01-5 |

| 7.50-16 |

220 |

2120 |

1800 |

Z1-01-4 |

|

| 7.00/6.50-16 |

200 |

2049 |

1600 |

Z1-01-4 |

|

| 7.50-15 |

200 |

1970 |

1620 |

Z1-01-4 |

|

| 7.00/6.50-15 |

190 |

1890 |

1500 |

Z1-01-4 |

|

| Industrial tires and other series |

6.00-15 |

187 |

1872 |

1250 |

Z1-01-1 |

| 6.50-10 |

175 |

1569 |

980 |

Z1-01-2 |

|

| 6.00-16 |

187 |

1619 |

1350 |

Z1-01-1 |

|

| 6.00-14 |

170 |

1700 |

1100 |

Z1-02-1 |

|

| 4.00/4.50/5.00-14 |

120 |

1590 |

700 |

Z1-02-1 |

|

| 6.00-13 |

150 |

1600 |

1100 |

Z1-02-1 |

|

| 6.00-12 |

191 |

1651 |

1100 |

Z1-02-2 |

|

| 5.00-12 |

119 |

1470 |

750 |

Z1-02-1 |

|

| 4.50-12 |

119 |

1470 |

750 |

Z1-02-1 |

|

| 4.00-12 |

115 |

1399 |

650 |

Z1-02-2 |

|

| 28*9-15 |

190 |

2105 |

1850 |

Z1-01-4 |

2.1 bias tire cushion belt technical indicators

| experimental project |

Unit |

Index requirements |

| Tensile strength |

Mpa |

≥7.0 |

| Elongation at break |

% |

≥350 |

| Tearing permanent deformation |

% |

≤40 |

| Hardness |

(ShawAType) degree |

60±8 |

2.2 specifications and dimensions

| Specifications |

Flatten width (≥mm) |

Intermediate thickness(≥mm) |

Edge thickness (≤mm) |

| 23.50-25 |

498 |

9.0 |

1.5 |

| 20.50-25 |

375 |

8.0 |

1.5 |

| 17.50-25 |

315 |

7.5 |

1.5 |

| 14.00-24 |

225 |

7.0 |

1.5 |

| 14.00-20 |

225 |

7.0 |

1.5 |

| 12.00-20 |

205 |

6.0 |

1.5 |

| 11.00/10.00-20 |

200 |

5.5 |

1.5 |

| 9.00-20 |

178 |

4.5 |

1.5 |

| 8.25-20 |

178 |

4.0 |

1.5 |

| 9.00/8.25-16 |

178 |

4.0 |

1.5 |

| 7.50-16 |

168 |

4.0 |

1.0 |

| 7.50-15 |

168 |

4.0 |

1.0 |

| 7.00/6.50-15 |

157 |

4.0 |

1.0 |

| 7.00/6.50-16 |

157 |

4.0 |

1.0 |

3.1 all-steel tire cushion belt technical indicators

| experimental project |

Unit |

Index requirements |

| Tensile strength |

Mpa |

≥10 |

| Elongation at break |

% |

≥400 |

| Tearing permanent deformation |

% |

≤40 |

| Hardness |

(ShawAType) degree |

60±8 |

Specifications and Dimensions of 3.2 Steel Tire Belt

| Specifications |

Flatten width (≥mm) |

Intermediate thickness(≥mm) |

Edge thickness (≤mm) |

| 12.00R20 |

235 |

8.0 |

1.0 |

| 11.00R20 |

225 |

7.0 |

1.0 |

| 10.00/9.00R20 |

215 |

7.0 |

1.0 |

| 825R20 |

192 |

6.0 |

1.0 |

| 8.25/7.50R16 |

183 |

5.5 |

1.0 |

| 7.00/6.50R16 |

175 |

5.5 |

1.0 |

Specifications and Basic Parameters of 4.1 Flexible Rubber Joint

| Nominal diameterDN(mm) |

KDTFLength (mm) |

Nominal diameterDN(mm) |

KDTFLength (mm) |

| 40 |

95 |

100 |

150 |

| 50 |

105 |

125 |

165 |

| 65 |

115 |

150 |

180 |

| 80 |

135 |

200 |

190 |